Super-High Density Olive Trials (Olivais do Sul S. L., Portugal)

Executive Summary

Throughout the trial the olive grove was in good health at the time of harvest the overall yield has been above average. Some small loss of olives can be discounted due to low level of Prays oleae (OliveMoth).

From the results of the trials, we are able to draw the following conclusions:

Average Fruit Weight and Fruit Density

The average weight of the fruit compared to the “Farm Standard” Control reference plots (Tables 2 and 3), shows a very remarkable increase in the “OptiYield Treated” plots, where the average shows a 19.92% yield increase in the first trial and 22.22% yield increase in the second over the Control.

It should be noted that the mean weights between both trials are very similar as they were measured within 10 days of each other. However the average weight shows a tendency to increase from the first to the second (later) trial.

Also note the important difference in fruit density (number of fruits / kg, table 2), which in table olives could have a great interest. It is possible that in these OptiYield treated plots better vegetative growth may have influenced this difference in weight; it should be noted that these plots are in their second year with the OptiYield programme.

Oil Yield

The oil content percentage of 15.6% in the OptiYield plots is also significant in relation to the Control of 13.87% – an oil content increase of 12.44% for OptiYield over the Control.

Oil Quality

From the data obtained there are no statistically significant differences in the mineral quality of the oil and thus samples from both the Farm Standard and OptiYield Treated plots are of equal quality.

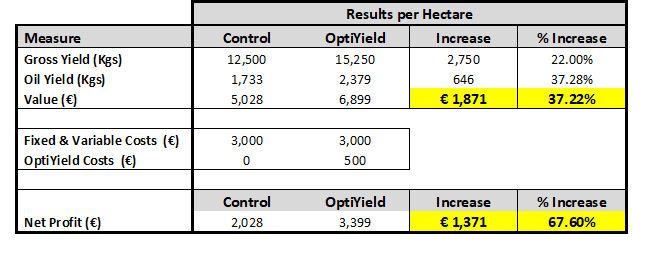

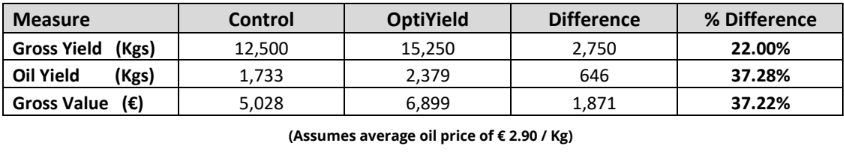

Economic Analysis

The combination of increased Gross Yield and increased Oil Content combine to deliver a very significant increase in total oil production per hectare of 37.22% (2,379 Kgs) over the Control programme (1,733 Kgs).

At an assumed nominal oil value of €2.90 / Kg and at a standard production cost of €3,000 / hectare this provides an overall income difference of €1,871.22 (37.22%) and Net Profits of €2,027.88 (Control) and €3,599.10 (OptiYield, including cost of OptiYield products): a Net Profit increase of 77.47%.

Trial Detail

Olivais do Sul

Olivais do Sul was an ideal site to trial OptiYield as it represents the best of modern high output olive and olive oil production.

Olivais do Sul is a dynamic company with a young team specialising in olive growing, production and packaging of extra virgin olive oil of high quality.

Located in Alentejo, an area of excellence for the production of olive oil, Olivais do Sul has about 600ha of olive groves – in an intensive and super intensive farming system – and a processing unit with approximately 3,000 m2, equipped with the latest technology and a capacity of Extraction of approximately 4,500,000 liters.

Olivais do Sul is an innovative company, always looking for what is new and the most advanced methods to produce extra virgin olive oil of high quality. Due to this fact, its olive oil has already been awarded in several national and international competitions. It is a company certified with the ISO 22000 (Food Safety Management System), ISO 14001 (environmental management systems) and IFS (Requirements for any organisation operating in the food chain) recognising its investment in the quality of service that allows offer To

its customers a high efficiency service.

Currently, Olivais do Sul farm more than 600 ha of irrigated olive groves, using the modern olive groves in Copa (Intensive System) and Sebe (Super-Intensive System).

Olivais do Sul follow Integrated production cultivations, minimising the use of fertilisers and phytosanitary and optimising all agricultural tasks. Pest monitoring, use of treatment programmes and soil analysis for fertilisation are all techniques used.

New systems and equipment of Regadio reduce the water use, applying the same according to the needs of the olive trees at each moment of its vegetative cycle.

Since the implantation of the olive grove we do not mobilise the soil, maintaining spontaneous vegetation cover in the line and incorporating the pruning remains on the ground. With this we were able to increase the content of Organic Matter and avoid soil losses by erosion, contributing to CO2 fixation.

Oil production complies to the highest standards of food safety quality ( ISO 22000 ) with the press

equipped with modern technology and exhaustive quality controls.

Trial Objectives

Following positive results from the previous season’s small plot trials the key objective for these trials was to see whether these results could be repeated within larger scale field trials with particular reference to the influence of OptiYield on:

- Fruit yield

- Overall oil yield, oil content increase and oil quality

- Mineral content of the oil

Trial Operation

Location: Monte do Trigo; Olivais do Sul. Area: AZ 1

Owner: Olivais do Sul S.L.

Variety: Arbequina

Trial Size: 2 Hectares

Plantation Spacing: 3.75m between rows (hedges) and 1,35 metre spacing between trees. (2,000 olive trees / Hectare)

Soil Type: Sandy loam

Irrigation System: Drip irrigation

Fertilisers: By drip system supplemented by foliar applications

Fertiliser Season: March, August, September

Equipment: Large capacity atomizer; 500/600 Litres / Ha.

Method

From detailed soil analysis the OptiYield software system created full nutrient availability and Olive nutrition models and produced a full nutrition/biostimulant programme specific to the Olivais do Sul olive trial site (See Appendix 1).

Emerald Research Ltd. (ERL) provided the suite of nutrition and biostimulant products recommended by the OptiYield system. Two 1.0 hectare blocks of olives hedges were selected to receive the OptiYield treatments (2.0 hectares total). Applications were made by the grower in accordance with the recommendations provided by OptiYield.

The Control blocks consisted of adjacent areas treated in accordance with farm standard practice and based on the normal fertiliser programmes followed in Portugal using standard soil analysis and recommendation methods (2.0 hectares total). Applications were made by the grower in accordance with these standard recommendations.

Assessments were conducted jointly by Conser Biologica and field staff of the grower (Olivais do Sul S.L.).

Trial Results

Visual assessments showed little appreciable differences between leaves, fruit and shoots.

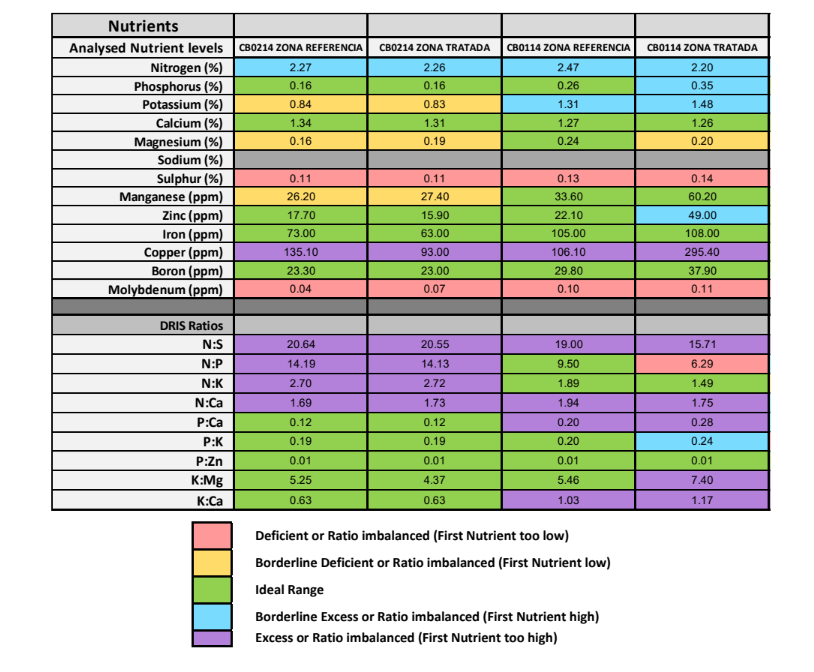

Foliar Analysis

At the end of the first treatments phase (H state, advanced) foliar analysis was conducted to compare the Control with the OptiYield treatment. The results of the two program trials are detailed in the table below, of which we can make the following comments:

- There is a significant deficiency of S and Mo, although the latter has little importance in olive groves, the lack of S coincides with the general opinion for this crop of the importance of it.

- Ca and Mg are borderline, but with no significant difference between OptiYield and Control treatments.

- There is a significant excess of Cu in both treatments, which we believe can be attributed to treatments with copper fungicides, necessary to prevent attack of fungi and bacteria.

- There is a low level of N in relation to P; while this relation is very high for the S and Ca.

- P is balanced with K and Zn and imbalance with Ca.

- K is very high in relation to Mg and Ca.

Given the very significant differences in final olive yield, oil content and overall oil yield between the two trial treatments the leaf tissue analysis results appear to provide a poor indication of overall crop performance beyond the level of “sufficient” or “deficient”.

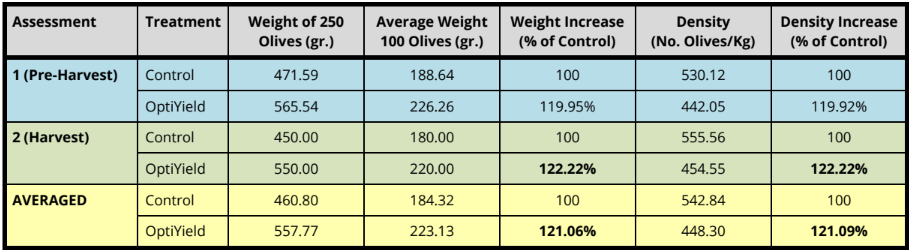

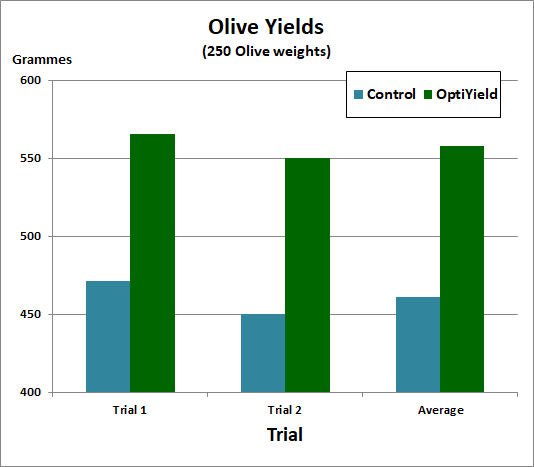

Olive Yield Assessments

Two assessments were carried out, the first one 10 days prior to harvest, and with the fruit already close to maturity. The second assessment is performed at the time of harvest.

Representative samples are collected from both the OptiYield treated and Control areas from the central rows/hedges from 8 different points. Fruits are chosen randomly from both the left and right sides of the row with 50 fruits sampled for each olive tree, in the different surroundings and heights to yield an average of than 400 fruits (olives) per sample.

Once collected they are well mixed and 250 fruits are selected from both the OptiYield treated and Control samples and their weight is measured in the laboratory. The data are shown in the tables below:

The data clearly demonstrate overall increases of 21.06% (Yield Weight) and 21.09% (Density) of the OptiYield treatment compared to the Control, where the Density measurement reflects both larger olives and higher oil content.

At the time of harvest the weight increase was at its greatest at 22.22% higher than the Control.

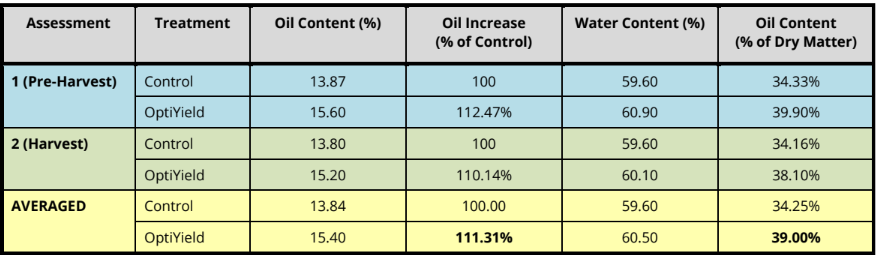

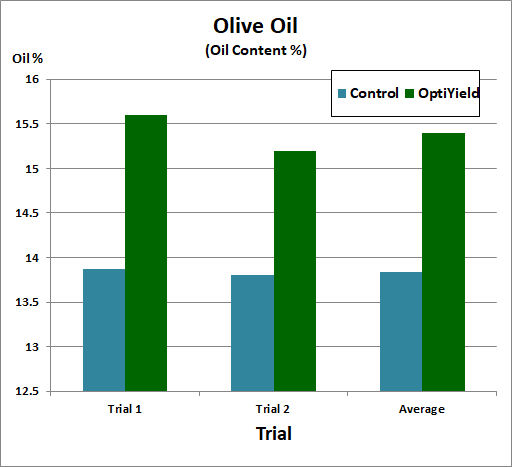

Olive Oil Content

Olive oil from the samples was extracted and the analysis performed by the laboratory of the Regulatory Council of Sierra Magina (Jaén).

The data clearly demonstrate overall increases of 11.31% (Oil Content) of the OptiYield treatment compared to the Control.

At the time of harvest the Oil Content increase was at 10.14% higher than the Control.

Economic Analysis

The combination of increased Gross Yield and increased Oil Content combine to deliver a very significant increase in total oil production per hectare:

Net Profit

For the grower the most important measure of success is Net Profit.

The cost of the full OptiYield programme is estimated at € 300 / hectare.

The average fixed and variable costs for olive production (cultivation, harvest and processing) is estimated at € 3,000 / hectare.

Based on these figures and the oil production figures the following calculations for Net Profit can be made: